DuraPack Python Side Loader

Durable. Fast. Smooth. The high-performance side-load garbage truck.

Engineered for Speed. Built for Strength.

Proven to Last.

Proven Power and Performance.

The DuraPack® Python® automated side loader combines two of Heil’s most trusted designs in one high-performance package. The DuraPack body is legendary for toughness and productivity, while the patented Python arm delivers unmatched speed, smoothness, and longevity. Together, they set the standard for efficiency and reliability in automated collection, helping fleets operate smarter and more profitably.

Continuous Productivity.

The DuraPack body’s follower panel allows continuous dumping during the pack cycle, so operators can collect the next cart without waiting. Twin packing cylinders achieve outstanding payloads, enabling more homes per route and reducing trips to the disposal site. Every detail is designed to keep operators efficient, routes productive, and fleets running at maximum performance day after day.

Speed that Pays for Itself.

With one of the fastest lift cycles in the industry, the DuraPack Python helps fleets finish routes faster and cut operating costs, saving up to $15,000 per truck each year. Its eight-second lift cycle shaves four seconds per stop, adding up to an hour saved per day compared to competing models. The Auto Lift feature automates lifting of the cart into the dump position in one smooth motion with a single press of a button. Together, these features deliver more productivity

Built Tough For Real World Conditions.

A fully welded, interlaced subframe resists abrasion, corrosion, and salt damage for exceptional longevity in demanding collection environments. The body is built with 7- and 8-gauge high tensile steel, while the hopper features a ¼-inch AR400 floor and 3⁄16-inch AR400 sides for superior strength and durability. High-tensile steel withstands intense compaction forces to deliver maximum payloads with fewer trips. The reinforced tailgate prevents buckling and includes a 60-inch seal to keep liquids securely contained.

Strength You Can Count On.

The Python arm lifts up to 800 pounds, with cushioned cylinders delivering smooth, controlled motion and protect both the arm and chassis from wear. Precision geometry minimizes spillage and ensures carts are consistently returned with lids closed. DuraPack Python’s optimized weight provides exceptional durability and higher payloads, dependable performance and the lowest Total Cost of Collection (TCC).

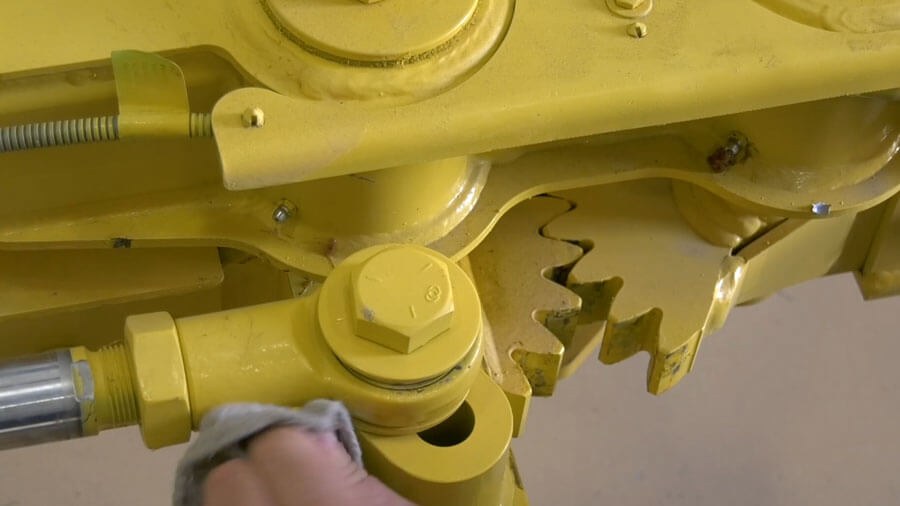

Reliability and Longevity Come Standard.

The Python lift arm’s hardened grabber gears, made from high-strength alloy steel, virtually eliminate wear and can last up to 1,000,000 cycles. The Heil DuraMount design secures the lift to the chassis frame to reduce bolt fatigue and improve stability, while Service Smart bolt access simplifies maintenance. These features ensure years of reliable performance, minimal downtime,keeping your fleet operating at its best.

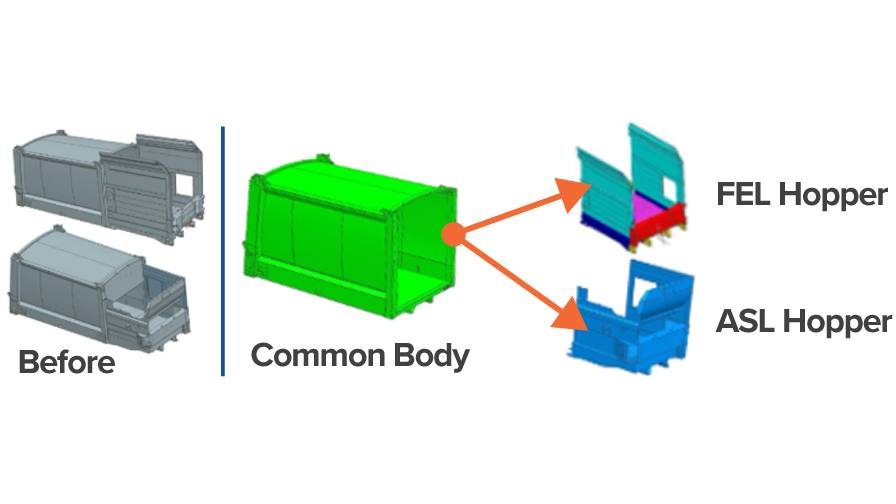

Every Route. One Body.

Introducing the engineering innovations of the Heil universal FEL/ASL body.

OPERATOR EXPERIENCE

Designed with your operators in mind. Driver-designed, ergonomic controls and a simplified interface reduce cab clutter and cut in-cab buttons by 66%, delivering a consistent, intuitive experience.

Common Body Parts

Standardized parts simplify operations. A shared body design with 44% or more common components means fewer parts to stock, easier technician training, and reduced downtime across both front and side load fleets.

In-Cab Display

The in-cab display provides real-time feedback and full body control, putting all key information in one place. Maintenance teams can quickly diagnose issues away from hazards and weather, while integrated 3rd Eye camera feeds remove the need for a separate monitor.

Integrated Cameras/Lights

Integrated 3rd Eye cameras come built into the body for better protection, less maintenance, and clearer visibility, all with fewer failures, less downtime, and improved safety, performance, and reliability in every environment.

Ease of Maintenance

Maintenance is faster and easier with improved access, fewer tools, and a centralized display for diagnostics, 3rd Eye feeds, and body performance data, plus relocated tailgate locks for cleaner, more convenient access.

Shur-Lock Tailgate

Tailgate cylinders are now positioned in the tailgate bolster, away from payload, for cleaner operation. This design simplifies tag axle function and removes hydraulic components from the tag axle area. All tailgate commands are controlled through the touchscreen display, preventing accidental movement during transit.

DuraPack Python ADD-ON Features

Integrated Lift Cam/Light

This integrated camera and light package provides the operator an exceptional view of the lift and surrounding environment.

CNrG Tailgate

The lower profile, fully integrated CNrG® tailgate fuel delivery system will revolutionize the way you use CNG garbage trucks.

3rd Eye Digital Package

Connect for service verification, fuel tax reporting, and route management with factory-installed 3rd Eye® Mobile, supporting up to six cameras.

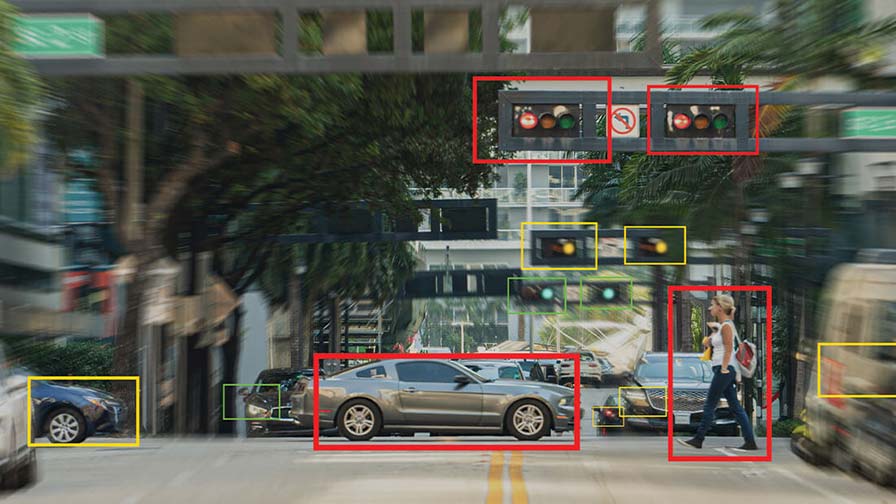

3rd Eye Safety Technology

Increase safety and awareness with factory-installed 3rd Eye AI-powered safety technology, plus 360° visibility and reverse automatic braking.

OPTIONAL 3RD EYE DIGITAL PACKAGES

Connect your DuraPack Python sideload garbage truck and other vehicles in your fleet for service verification, body/chassis data, fuel tax reporting, and route management. Includes factory installed 3rd Eye® Mobile, Radar System, and the ability to connect up to six cameras.

THE POWER OF Connected collections

Fleets face continued frustration around their ability to connect with their customers. Fleet owners need better tools to communicate with their drivers – to ensure customer needs are met – while also ensuring they are operating efficiently… and safely. Introducing Connected Collections from Environmental Solutions Group companies, Soft-Pak®, Heil, and 3rd Eye. Together, we’ve developed Connected Collections to help fleet owners make better decisions faster.

DuraPack Python RESOURCES

GENUINE OEM GARBAGE TRUCK PARTS

Heil Certified OEM parts are the most reliable replacement parts for Heil refuse collection vehicles. They’re made following the exact specifications and production processes on the same assembly lines as the parts originally installed on the bodies. This means that they fit perfectly every time. Heil uses only the highest-quality materials for parts that last – minimizing costly downtime. For more information on parts, contact your Heil dealer.